Hemming Lightweight Fabrics With a Serger & Sewing Machine

Maura Kang

We’ll show you the easiest way to make a rolled hem on chiffon fabric, or any other similar lightweight material. We’ll first demonstrate it on the serger, then with a domestic machine for those who don’t own a serger. Using the recommended materials and this technique, the result will be a beautiful rolled hem that looks just as professional as if it came from the store!

A lot of formalwear uses sheer, lightweight fabrics, and this method is a good way to keep the edge looking professional like it had never been modified. Apart from your machine, you’ll only need some small but important materials:

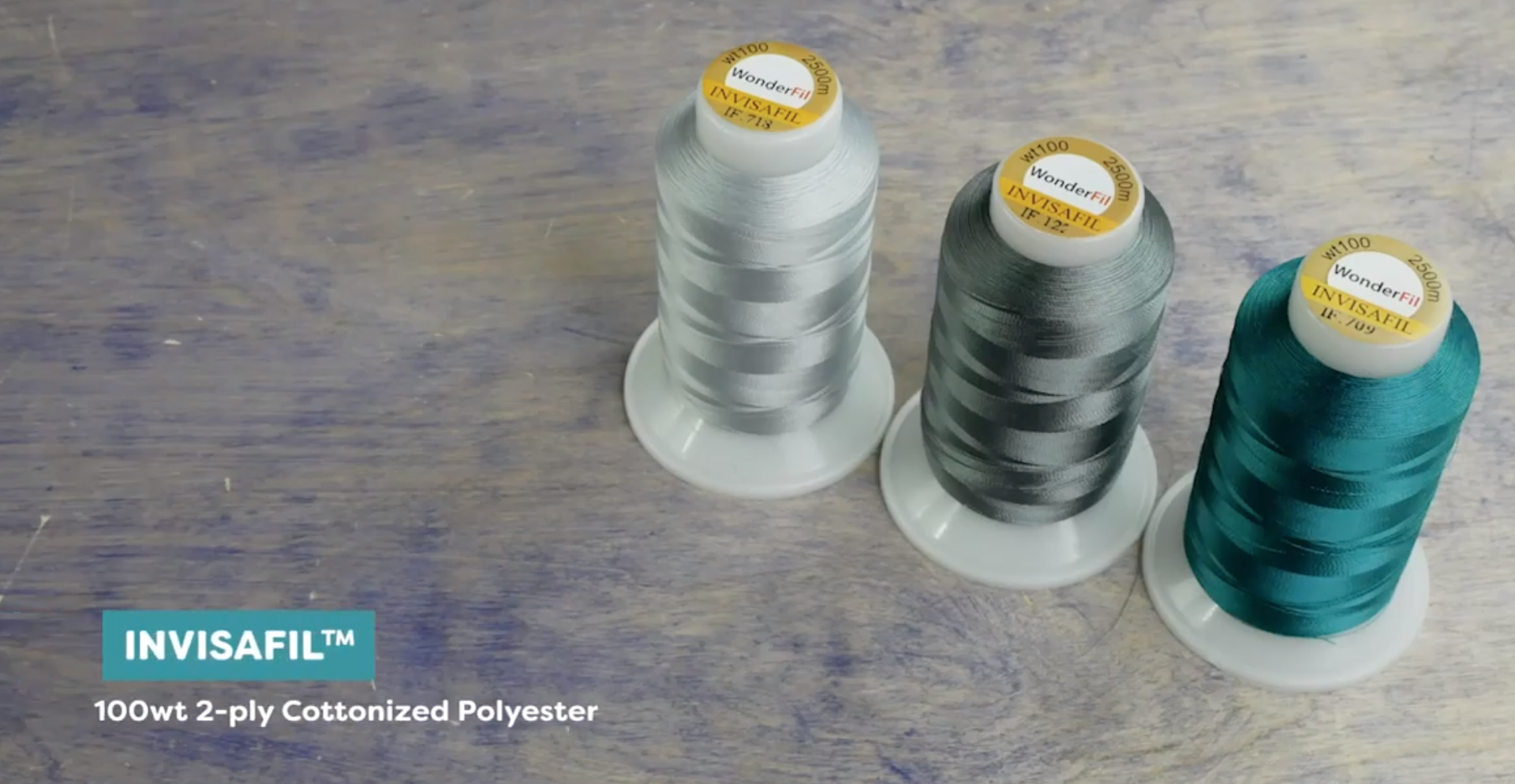

First, you’ll want to choose the right thread. We’ll be using a 100wt poly thread called InvisaFil, which is going to blend really well in the fabric so you don’t even see it. And because the thread is so fine, it will stitch more easily through the thin fabric, resulting in fewer ruffles. It’s important to use a very fine thread like this because apart from showing less, it also won’t weigh down the lightweight fabric either.

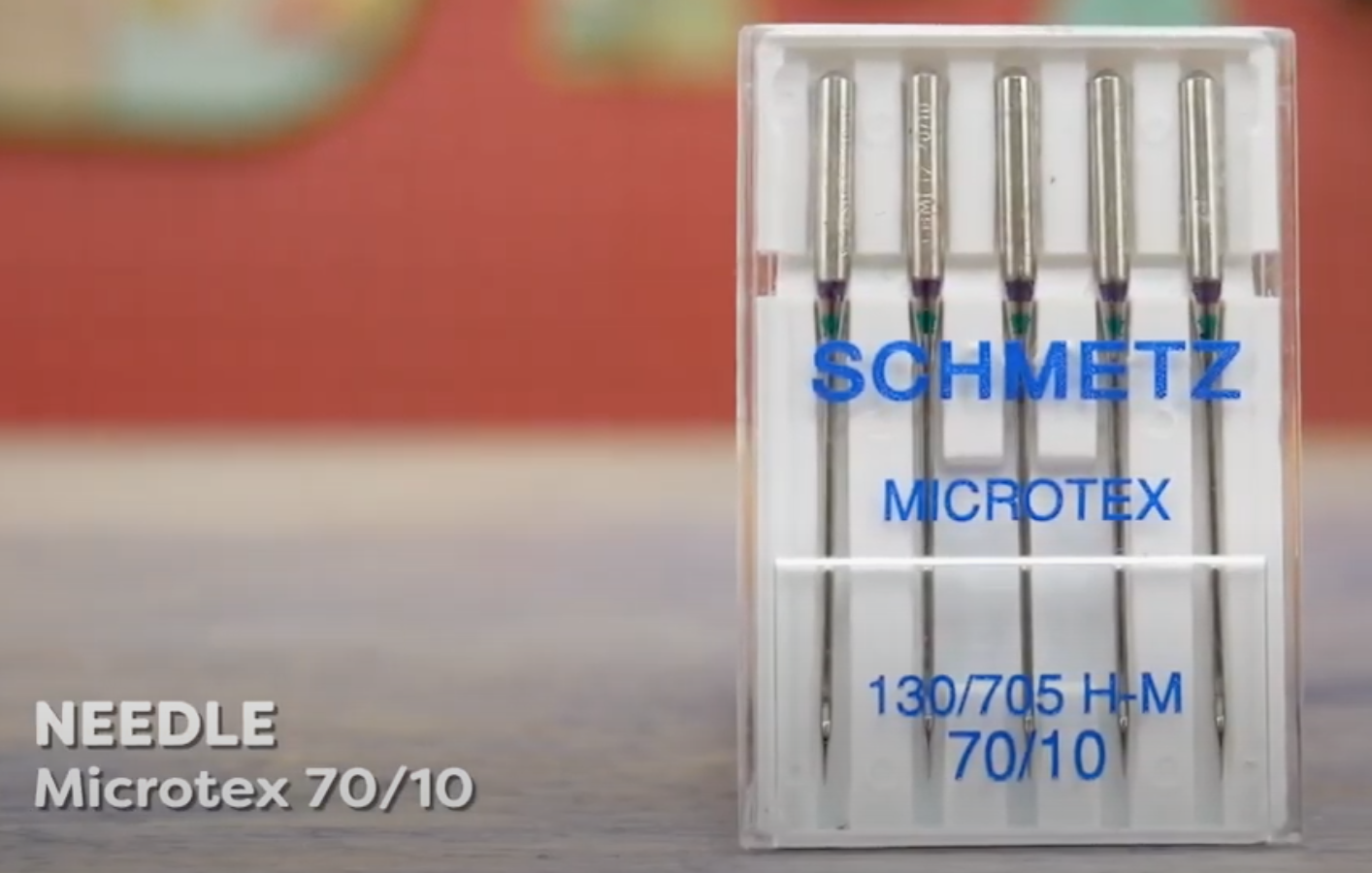

Because the thread is so fine, we’re also going to choose a needle with a smaller eye. Choose a size 60/8 or 70/10 microtex needle which works best on light fabrics.

Finally, I’m going to use a bobbin that’s been pre-wound with DecoBob thread. This is an 80wt poly thread that comes already pre-wound on a plastic sided bobbin which will pair well with the top thread. You can alternatively wind your own bobbin with the InvisaFil thread, just remember wind it slowly since the thin thread tends to float away. If you’re going to hem your fabric on a serger, obviously you won’t use a bobbin so you’ll want DecoBob thread on a spool for your lower loopers.

On a Serger:

We are going to use a 3 thread rolled hem, with InvisaFil in the needle and upper looper, and DecoBob in the lower looper. Consult with your serger manual and adjust the stitch length and cutting blade to get a close narrow hem.

Once your machine is threaded, do a test run on similar fabric to make sure your fabric is not puckering. You may have to adjust your differential settings to get a flat, smooth edge.

Mark your hem with a disappearing marking pen, and serge exactly along your marked line. This is the simplest method for a quick fine hem on chiffon or similar fine fabric.

On a Domestic Sewing Machine With a Rolled Hem:

If you want to hem fine fabric on a domestic machine, this two step method will help you achieve perfect results. Mark where you want your finished hem and cut 1” below the marked line. We will trim this closer later. Be sure to spread the fabric out flat and even as these types of fabrics can easily shift during cutting. Thread your machine with InvisaFil on top and DecoBob in the bobbin. Now you’re ready to sew!

Using your fingers, tuck the edge of the fabric over 1/8” below the finished hem length and stitch very close to this folded edge. Do this all the way to the end of the fabric. If you’re hemming a sleeve or skirt, or anything where your piece is a loop, we recommend starting and ending on the seam to help hide the backstitching.

When you’re done, use a pair of sharp, fine tipped scissors to cut away the remaining fabric as close as you can to your line of stitching without snipping into the stitching itself. Exercise caution so you don’t accidentally snip over your seam. Do this all the way to the end.

Press all the way around to sink the stitches into the fabric and smooth any puckers.

Once you’ve finished trimming the excess fabric and pressing, tuck the edge 1/8” over one more time (along the finished hem marking) and stitch it down again over the original line of stitching to complete your rolled hem. If you have trouble tucking the edge over with your fingers and keeping the 1/8” length consistent, you can press the edge down with an iron before sewing.

That’s all there is to it! You can see how little the thread shows in the finished hem as well how flat the edge sits because the fine thread doesn’t add extra bulk. As most hems have a curved edge, doing the hem in two steps helps keep your hem even and consistent and eliminates any problems. These materials combined with these simple techniques are all you need for perfect, professional hemming.

(Left: done with serger. Right: done with domestic machine.)

Inspired to sew? Head on over to shopwonderfil.com/shop-local/ for a list of stores and retailers you can purchase WonderFil threads from. You can also sign up to receive weekly sewing tips, free patterns, and tutorials in our newsletter. Register by clicking here! You can unsubscribe at any time by clicking the unsubscribe button on the footer of every email you receive.