Introducing the Bobbinator™ - A Unique Sewing Accessory

Maura Kang

Check out the Bobbinator on our Canadian online site for a closer look!

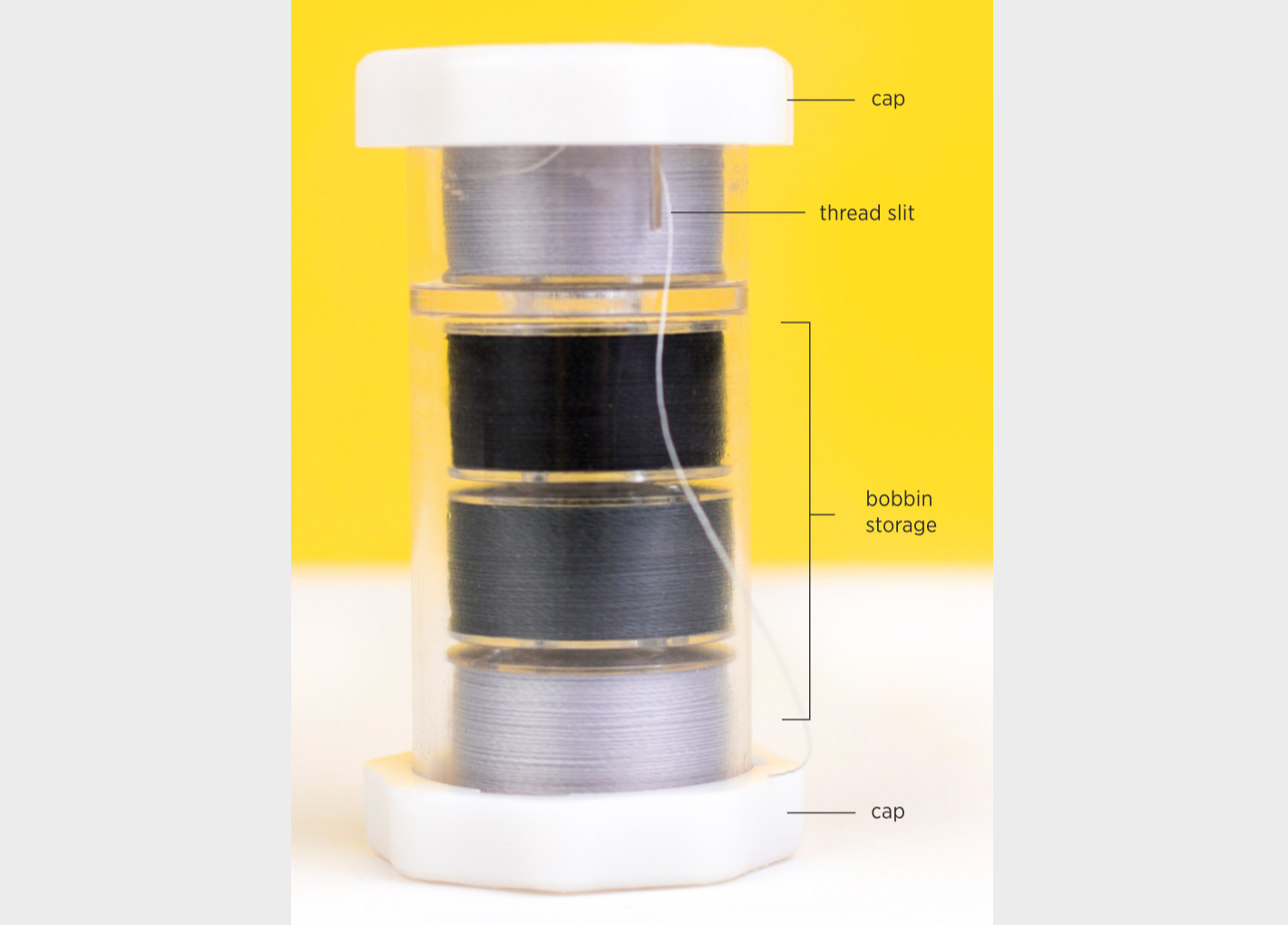

This unique item turns your bobbin into a spool of thread so that there is no need to purchase a separate top thread for small to medium sized projects! The Bobbinator includes a reserve chamber to keep 3 additional bobbins in storage, making it to easily store total of 4 bobbins.

The cap on each end of the device twists off, with one end opening to the storage chamber and the other end opening to the compartment that holds the bobbin you’ll be sewing with as a top thread.

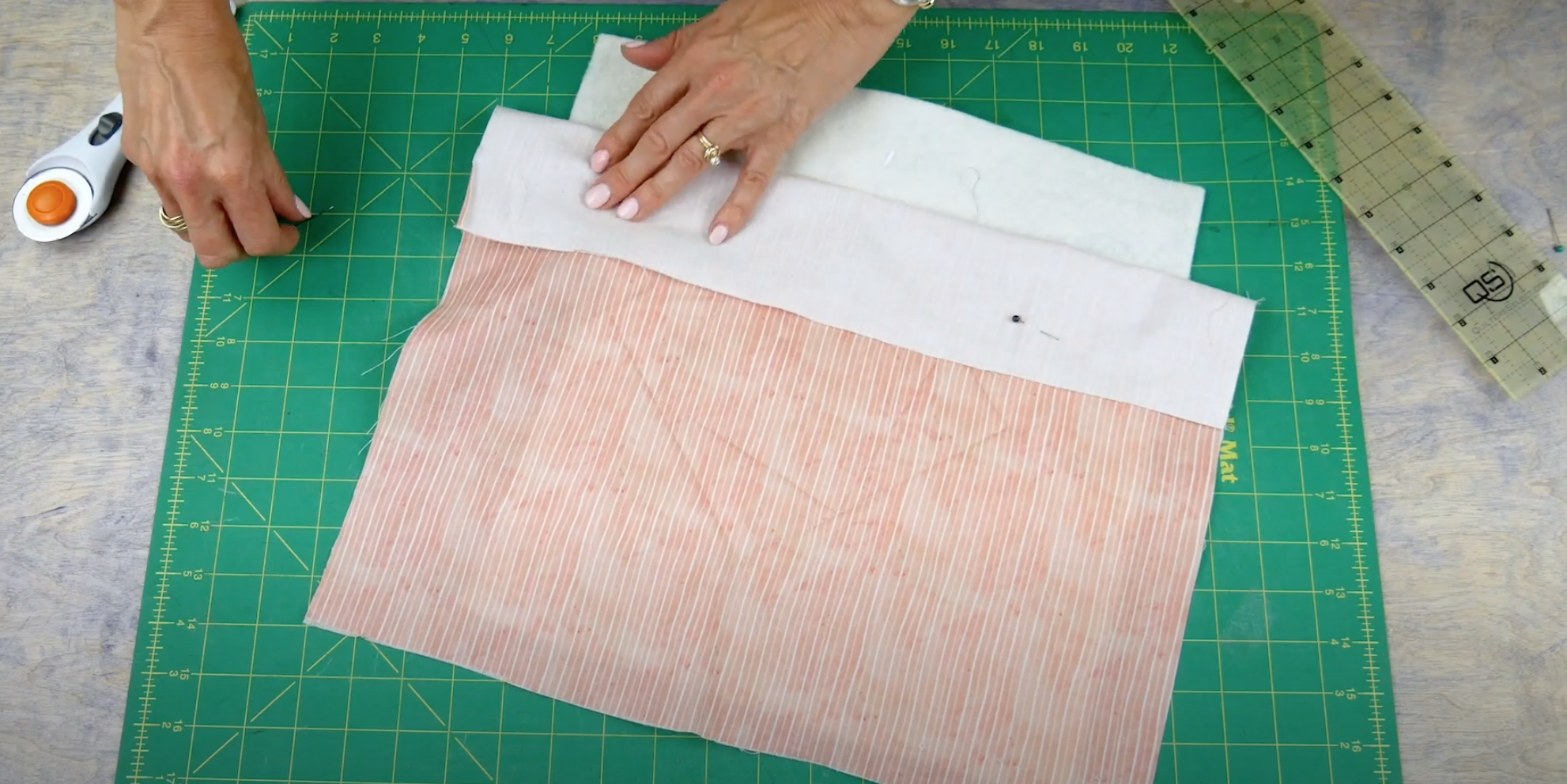

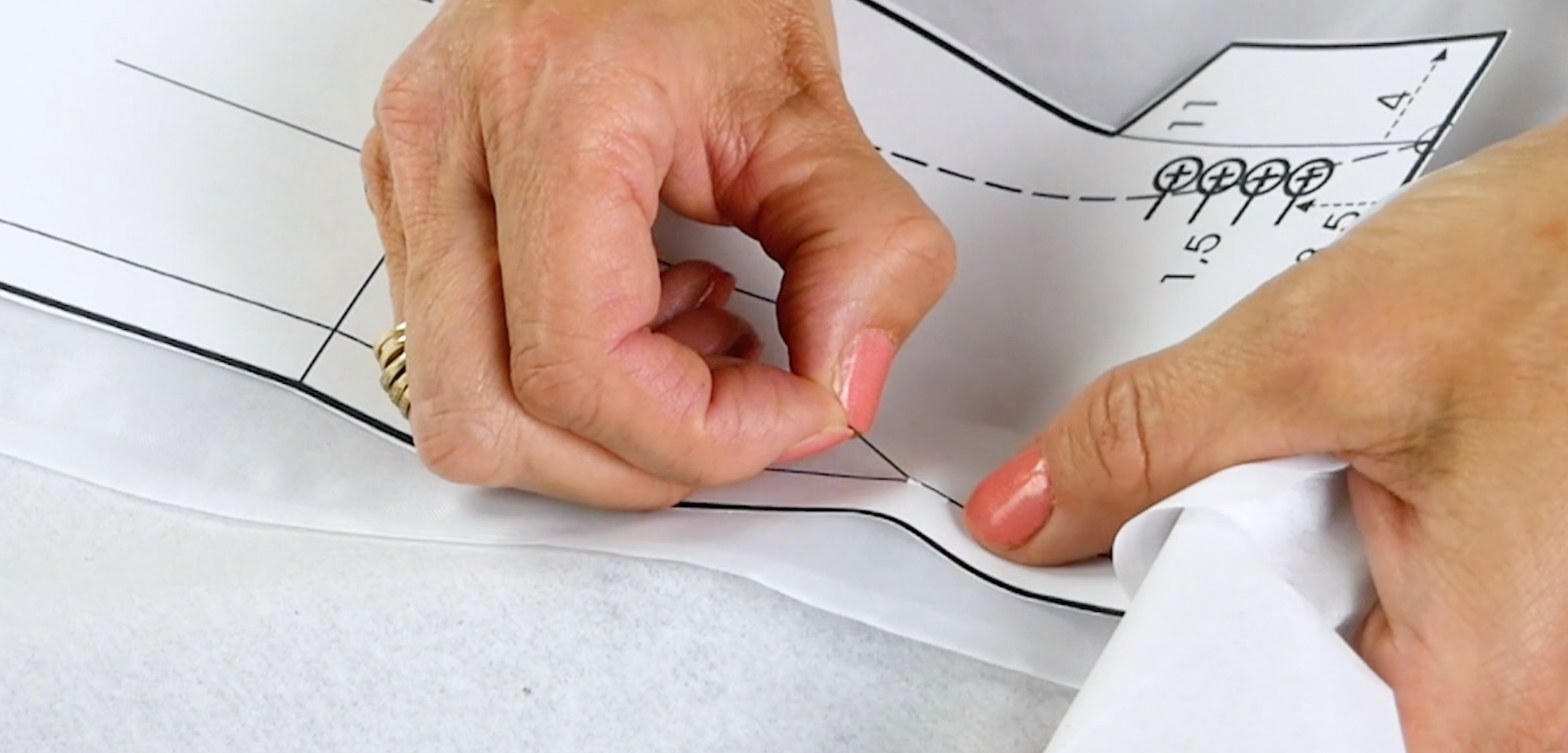

Simply drop a bobbin into the main compartment and draw the thread through the slit. Twist the cap back on and the Bobbinator device and you’re now ready to use the bobbin thread as a top thread on either the horizontal or vertical spool pin. After placing it on your thread pin of choice, simply thread your machine like normal. This handy device lifts the bobbin thread out so that it doesn’t drag against the edge of the bobbin, causing tension changes. This is perfect for bringing a few colours as needed to guild meetings, events, and classes instead of bringing your entire thread box.

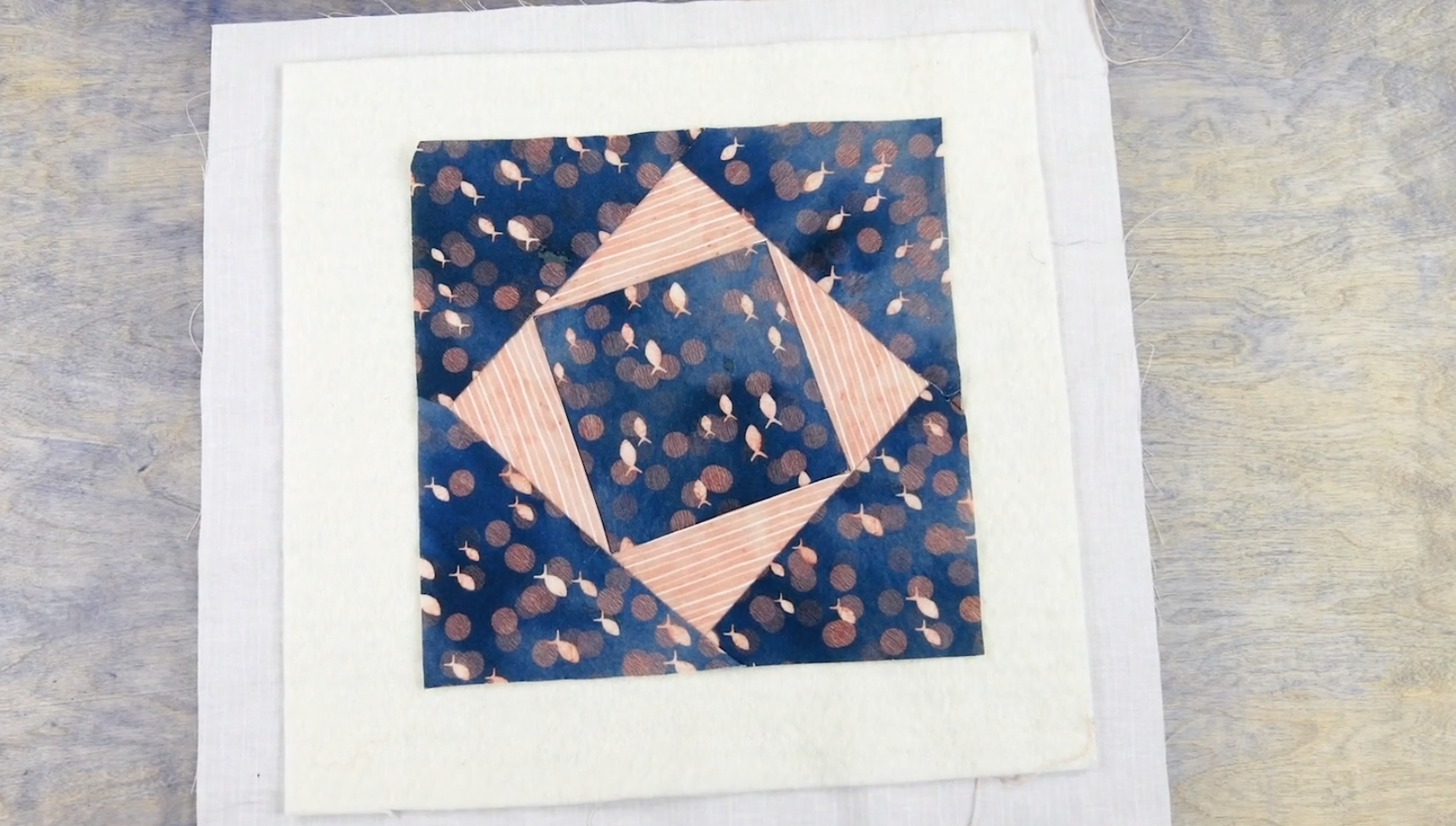

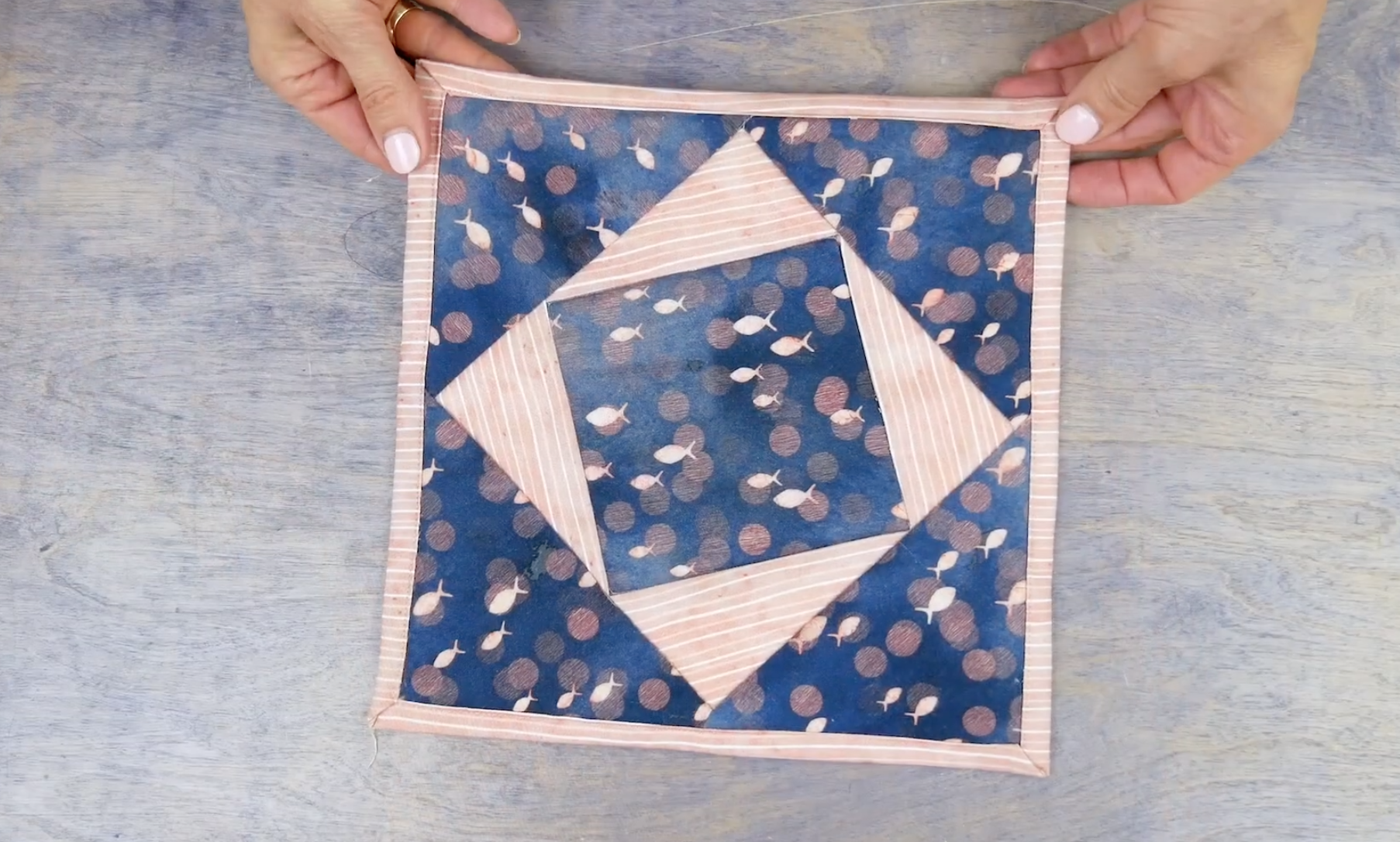

But you don’t need to just use it for machine sewing. Each bobbin included with this device is a DecoBob 80wt cottonized poly pre-wound bobbin. This thread makes for an ideal English paper piecing and hand appliqué thread as the super fine thread allows the fabric to sit tighter together and lay flatter, with the thread blending in so it won’t be seen. The Bobbinator makes it easy to keep the thread organized and tidy while you stitch at home or on the go.

DecoBob is also an excellent choice for hand and machine piecing, quilting, machine embroidery and digitized lace designs, button holes, and hidden stitches. Every Bobbinator pack includes 10 DecoBob pre-wound bobbins in your choice of grey or beige colours, as well as 1 Bobbinator device.

It also comes in a special variety made just for Sue Daley exclusively in her signature pink colour and her favourite 10 colours of DecoBob.

Included with every Bobbinator pack are prewound bobbins wound with our super fine 80wt DecoBob™ thread, an excellent bobbin thread that can be paired with any top thread. DecoBob™ is ideal for hand and machine piecing, quilting, machine embroidery and digitized lace designs, button holes, and hidden stitches. Enjoy with your bobbin thread as a top thread!

Want to try a Bobbinator for yourself or as a gift for that special friend? Find a store in your area that carries WonderFil at http://www.shopwonderfil.ca/shop-local. You can also sign up for our free newsletter to receive more educational sewing tips, tutorials, and free patterns. Register by clicking here! We’ll see you again next time!