10 Ways to Sew with Heavy 12wt Thread

Maura Kang

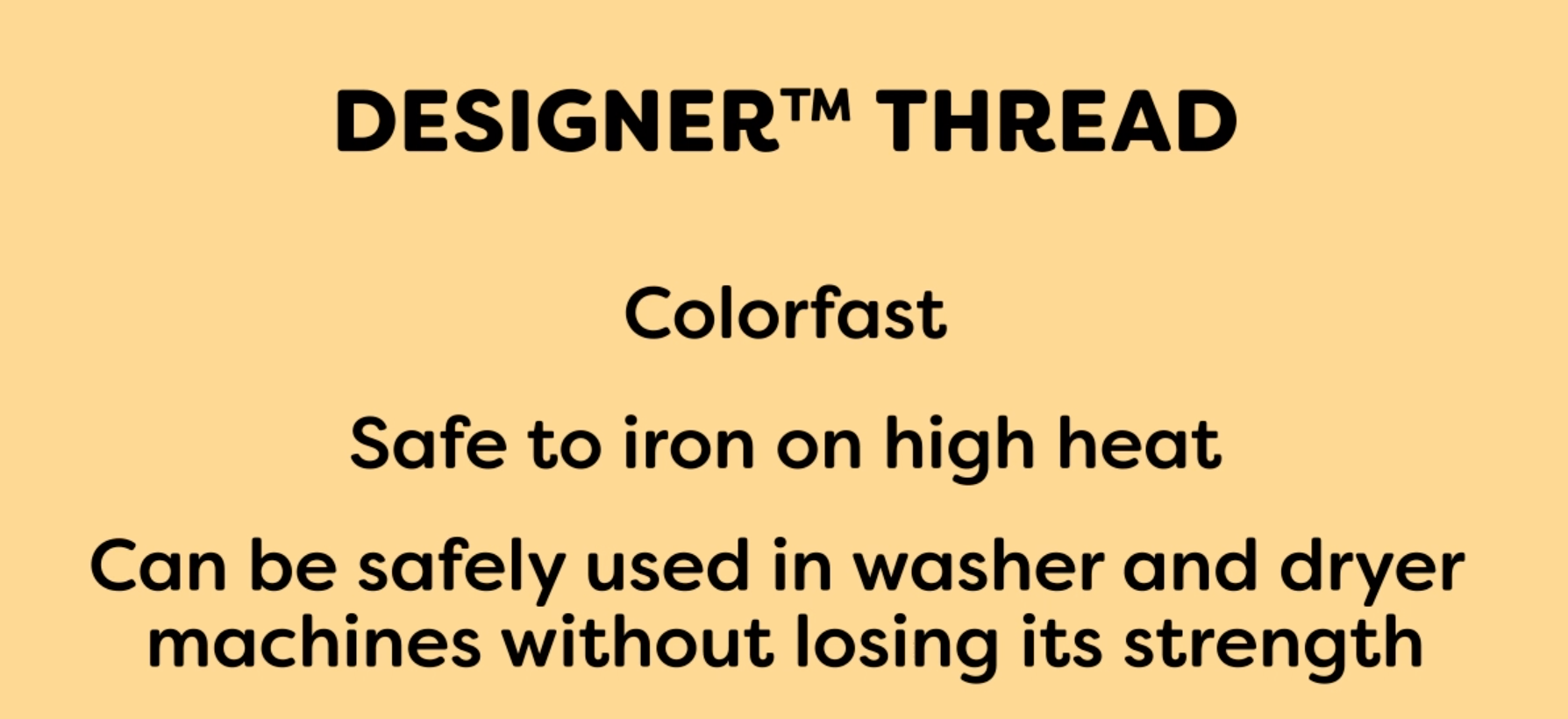

Some sewers might be stumped on what to use 12wt thread for, afterall it isn’t your traditional medium sized thread. What a lot of people don’t realize is how beautiful, bold, and versatile this thicker thread can be, and what kind of effects you can create with it. We’ll also take a closer look at the different types of 12wt thread you can find and when you might want to choose one over the other.

1. Thread Painting

12wt threads are a fantastic choice for thread painting for a few reasons. Because the thread is thicker, you can actually cover more area with less thread, making it a lot more efficient to thread paint with a 12wt thread. In addition, you’ll also find that the thread sits a little higher from the fabric. This gives a bolder textural effect to your project than using a medium weight thread would.

2. Cross Stitch

These threads are thick enough for cross stitching projects, especially when you want to use a fabric or fibre with a finer weave. In this project, we used Spagetti™ and Fruitti™ 12wt cotton threads, which pull smoothly through the fabric due to their ultra low lint finish.

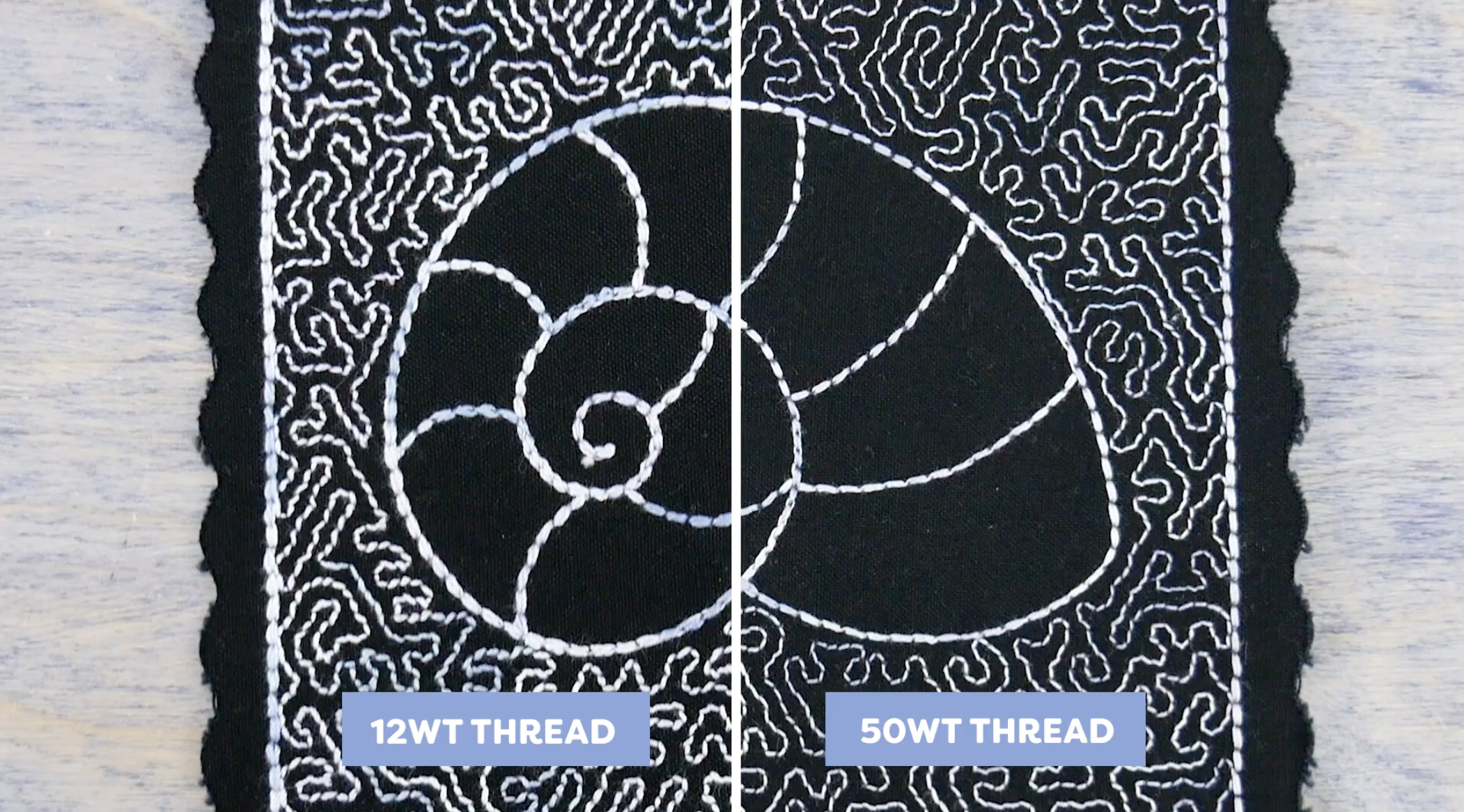

3. Machine Embroidery

40wt threads are the standard when it comes to machine embroidery, but you can create a new look by using 12wt thread in your embroidery machine. If you have a larger design, or a design that isn’t too intricate, a 12wt thread will show the pattern much more boldly without needing to double stitch the same lines. Your pattern will also show off better due to the thicker thread.

4. Hand Embroidery

If you love doing hand embroidery and sometimes split the strands of embroidery thread to make a finer thread, we would caution you against this. Splitting the strands of a thicker thread can weaken the thread while also giving it a lintier look. Instead of doing this, try using a 12wt thread which is comparable in size to an 8wt thread that’s been split in two. This way you won’t damage the thread, and you’ll keep your stitches looking clean and beautiful.

5. Decorative Stitching

The decorative stitches built into most sewing machines are perfect for utilizing 12wt threads for fun, stand-out stitches. They’re perfect for decorating any project, whether it’s a stocking for your family, adding a small decorative line of stitching to a piece of clothing, or embellishing any quilt or table runner. A 12wt thread will give every decorative stitch a little more emphasis than a regular medium weight thread would.

6. Needle Punch

Needle punching is a tool that can be used to create incredible textural effects, and it works best with thicker threads like 12wt. Depending on how you use the tool, you can make either dense loops or weave back and forth to fill in a space. This is a fantastic way to add a unique look to any project.

7. Big Stitch Hand Quilting

12wt is one of the best threads to use for big stitch hand quilting because the thick thread really stands out against the fabric. You’ll also find it easier to handle a 12wt thread versus a medium weight thread as it is less delicate and sits better in a wide running stitch.

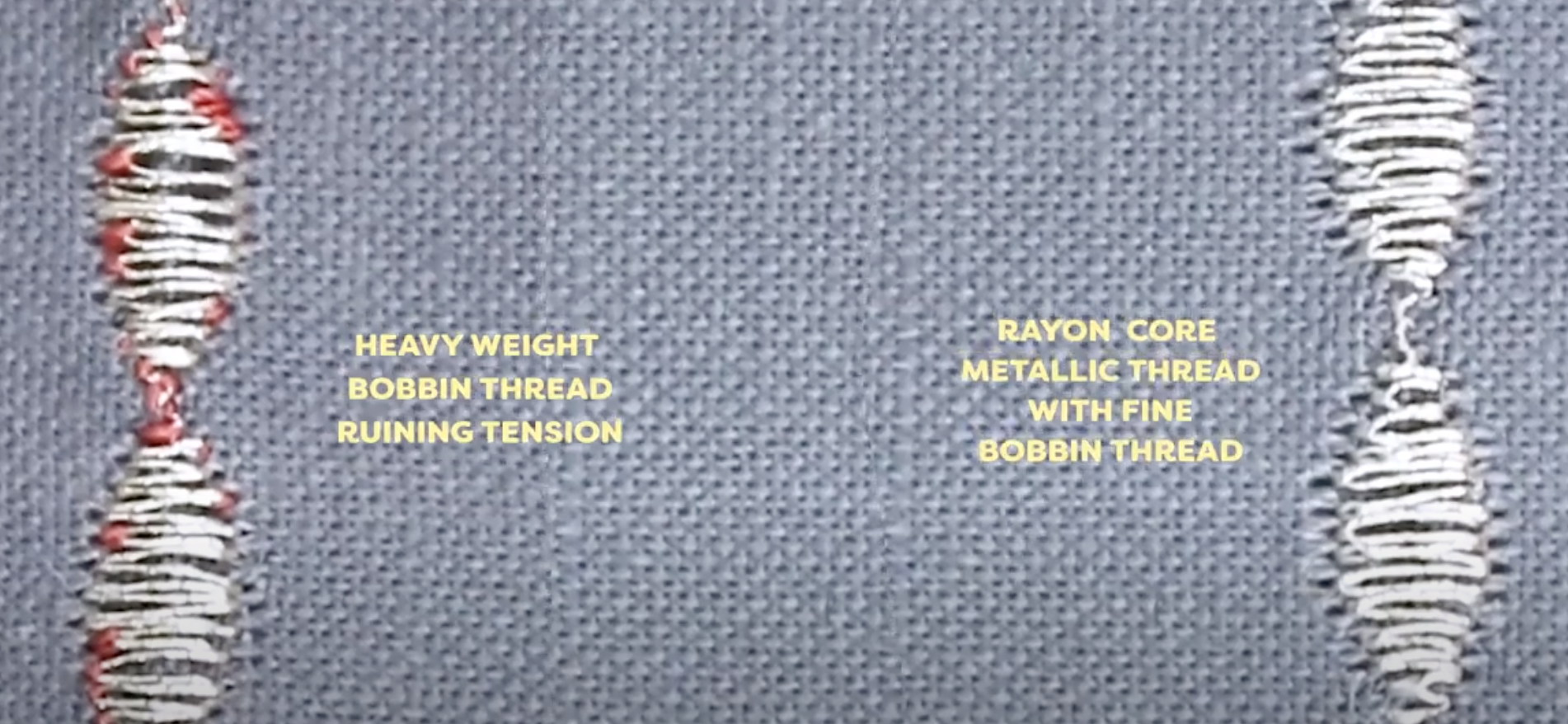

8. Machine Quilting & Longarm Quilting

If you’re not afraid of bold stitches that love to show off, a 12wt thread is the perfect choice when used for quilting. 12wt is actually the thickest thread you can put through the eye of a machine needle, so you can guarantee a quilted look where the thread adds another dimension of texture and colour.

9. Red Work

Red work is a form of American embroidery that traditionally uses red thread and basic stitches to decorate household items. It can be completed with a simple backstitch following a traced pattern to create motifs that can decorate anything from dishcloths to quilts to cushion covers. A 12wt thread stands out beautifully against white fabric, making it ideal for outlining patterns.

10. Sashiko

Sashiko is a Japanese embroidery technique that uses a simple running stitch to create beautiful geometric patterns or imagery. Traditionally they use white thread on an indigo dyed fabric, but these days, you can use any colours you like. Sashiko can be done by hand using a running stitch and a long hand embroidery or sashiko needle. However, you can also purchase a sashiko machine which replicates the look of a hand stitch.

Tell us in the comments where you’ve used 12wt threads, or where you would like to try them in a project! You can find a list of stores that carry WonderFil threads on www.shopwonderfil.com/shop-local/. You can also sign up to receive weekly sewing tips, free patterns, and tutorials in our newsletter. Register by clicking here! You can unsubscribe at any time by clicking the unsubscribe button on the footer of every email you receive.