Binding Quilts with Your Backing Fabric - No Binding Strips Needed!

Maura Kang

We want to show you a fabulous way of binding your quilts using just the backing fabric. It’s fast, easy, and still looks just as good as if you did it with binding strips. This is a wonderful way of simplifying your binding without sacrificing a professionally finished look!

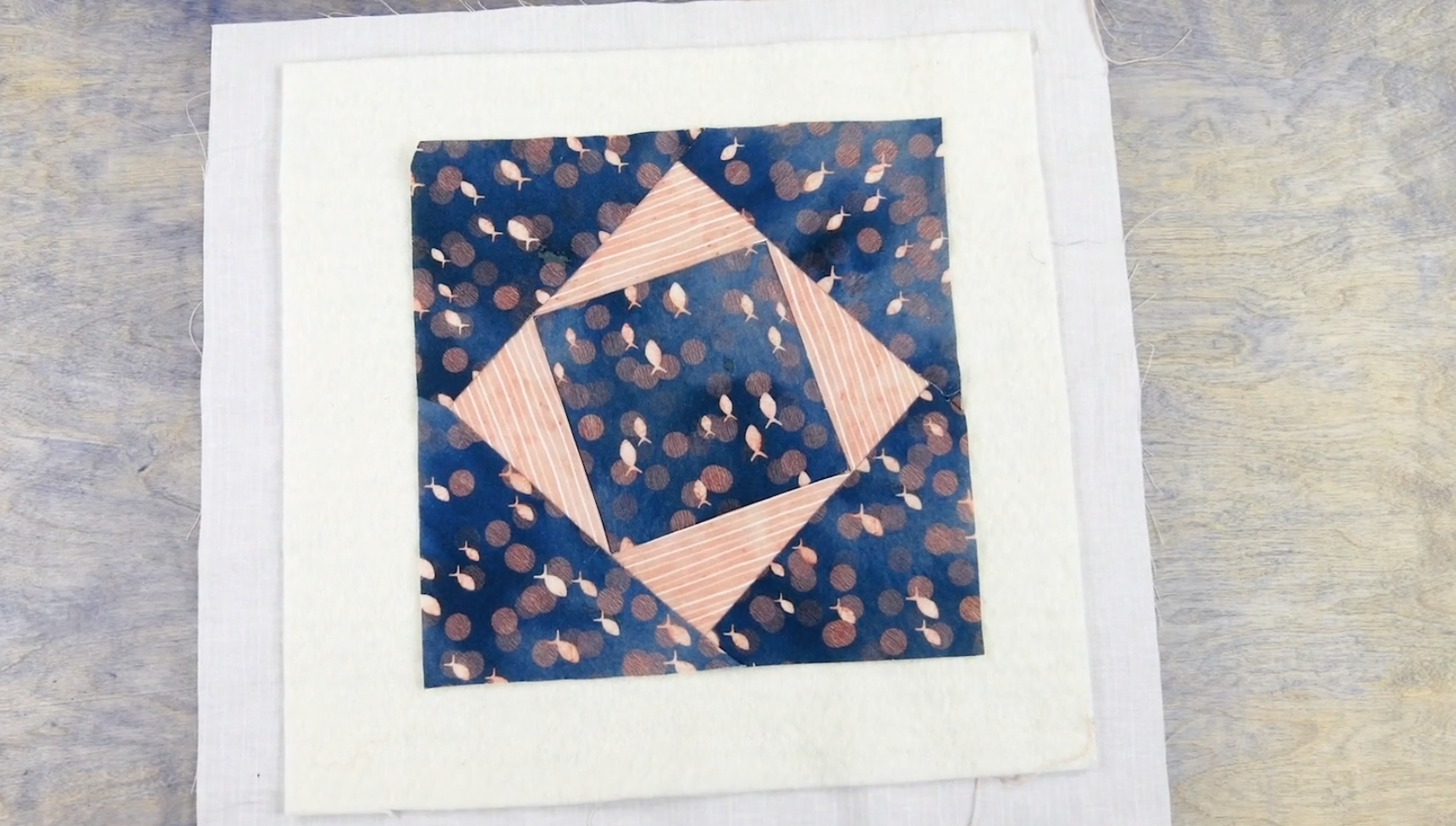

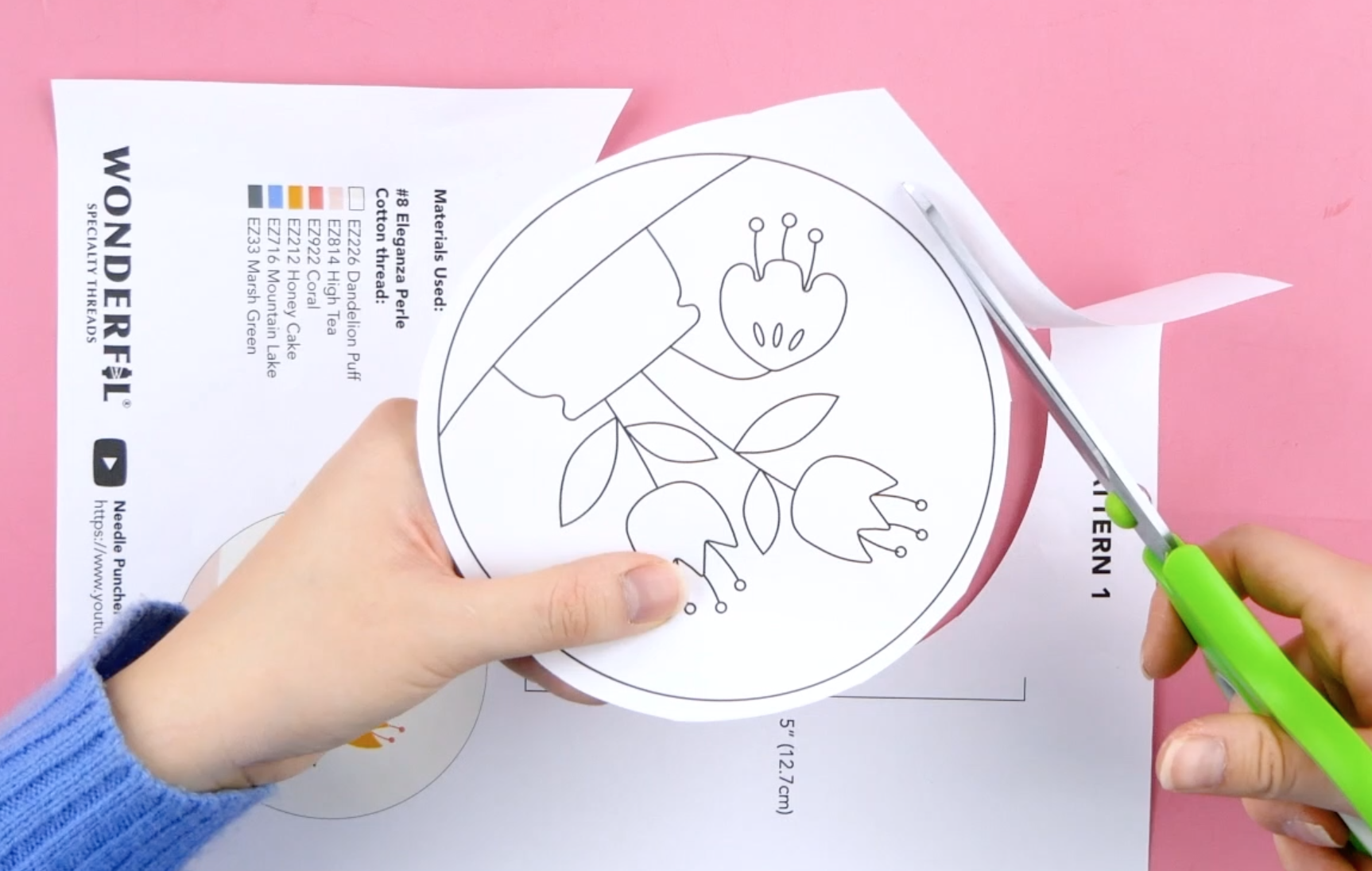

We’re using this quilt block as an example of how to set up your own quilt to bind it with the backing fabric. This method will of course still work on a larger sized quilt, but we’ll just be demonstrating the technique on this block.

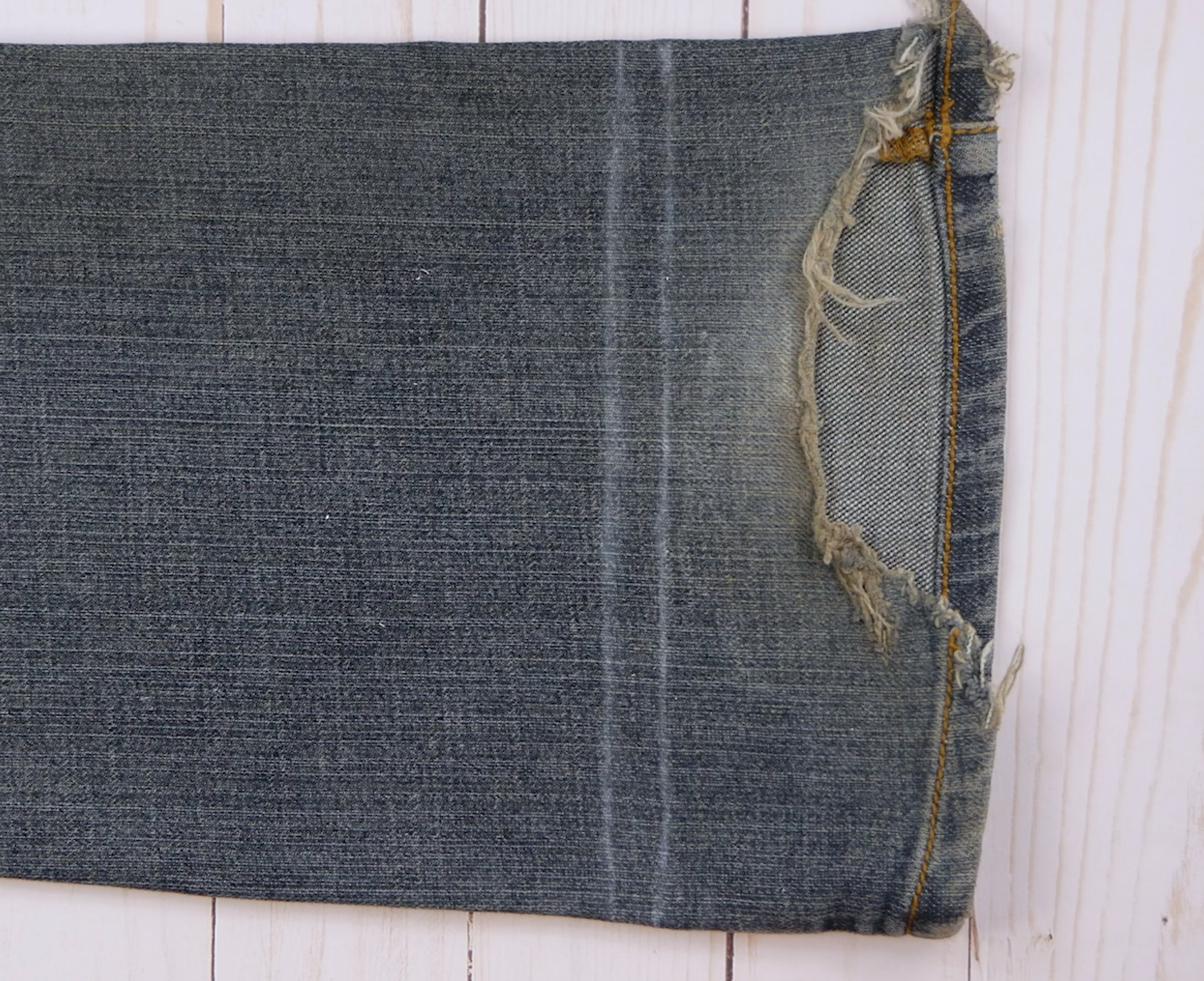

After your quilt has been quilted, you’ll have some leftover batting and backing fabric along the edges. If you plan on binding it with the backing fabric, you’ll need to leave an excess of about 2 or 3 inches of backing fabric.

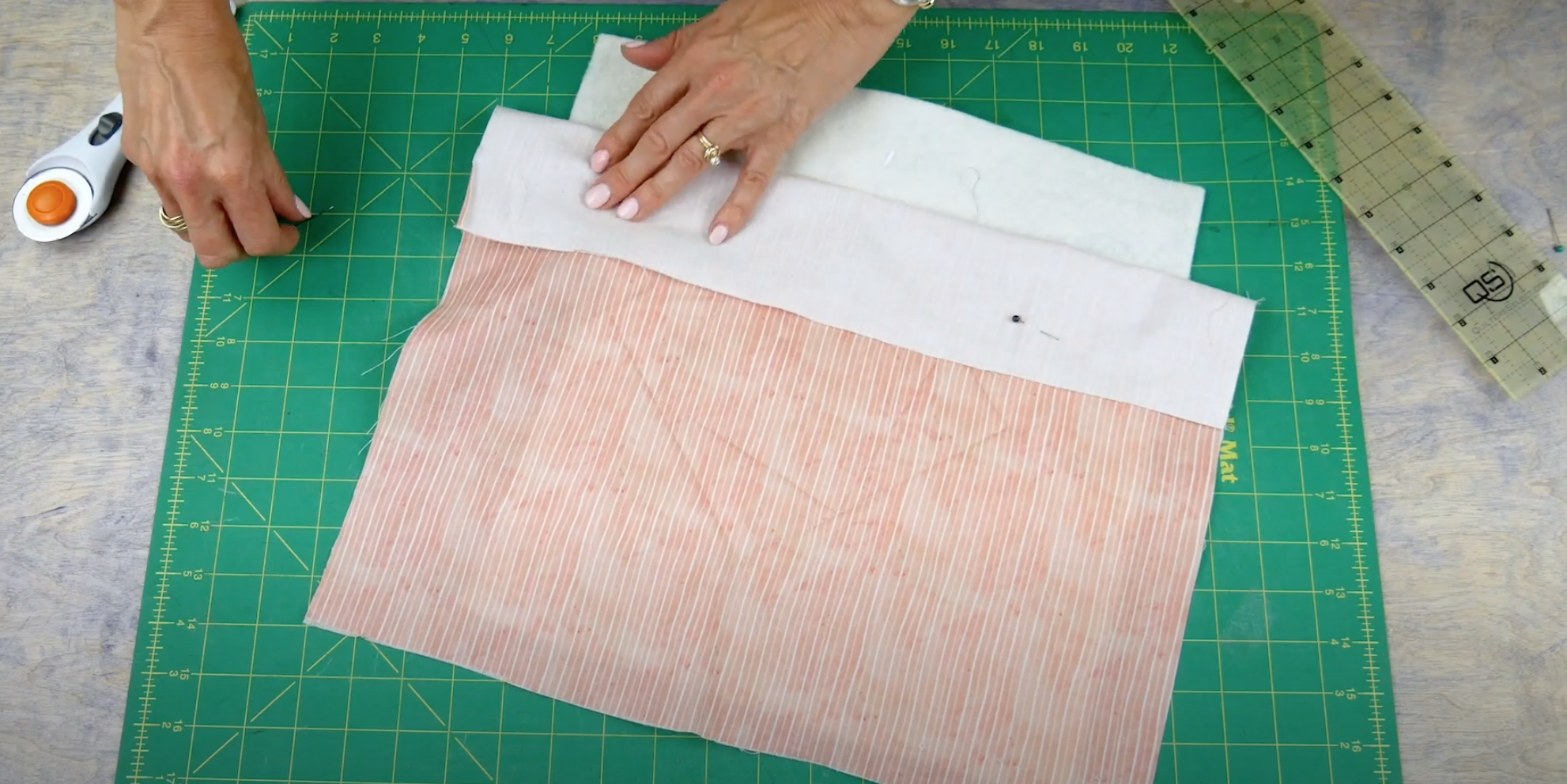

Before you can begin binding, you’ll need to square up your quilt. Tuck your backing out of the way and trim the other layers with your rotary cutter. Be careful not to cut through any of your backing fabric. If you can’t get your backing out of the way enough that you won’t cut into it, you can also carefully trim your layers with a pair of scissors as long as you can get it all squared up evenly.

(Pinning the backing fabric out of the way)

(Trimming the batting to square up the quilt)

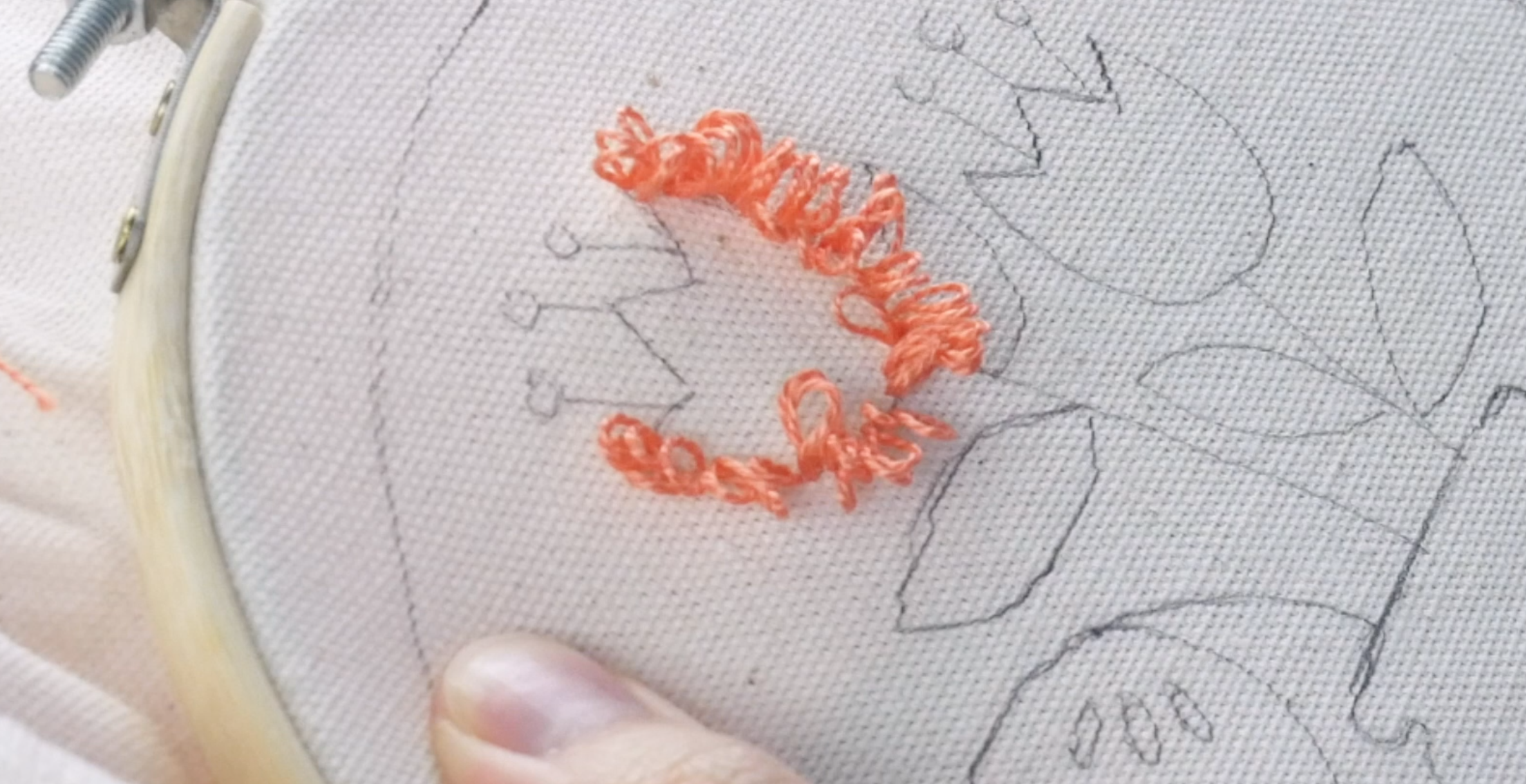

When your quilt is trimmed and squared up evenly, you can now trim your back fabric. You will need an inch of back fabric from the edge of your quilt, so take out your quilt ruler and trim it so that you have an even 1 inch of back fabric all the way around.

(Trimming the backing fabric to 1”/2.5cm

Fold your back fabric in half so that the edge of the fabric is just touching the edge of the quilt top. You don’t need it to overlap the quilt top, just have it lined up against the edge of it. Press with an iron to hold the fold in place.

Now you’re going to fold the binding over one more time. Take a glue stick and run it across your binding, then when you fold it down again it will help hold it in place. Press again with the iron to keep it stuck down snugly.

Now that you have your first folded edge, we’re going to fold the corner into a triangle making a 90 degree angle. Add another dab of glue and press it down with the iron to keep it in place.

Like before, fold the backing of the next edge down and press it in place with the iron. Take your glue stick and glue the entire edge including the folded triangle. Fold it over again and iron it down as you fold. The corner should have a perfectly mitered edge if your quilt is squared up correctly and the backing is folded evenly.

Continue these steps for the other two edges. When you come around to the last side, fold the corners on both ends of the backing into a 90 degree angle. Then fold and iron the binding down like before. Dab your glue across the entire fold including both corners and fold again, ironing it down as you go.

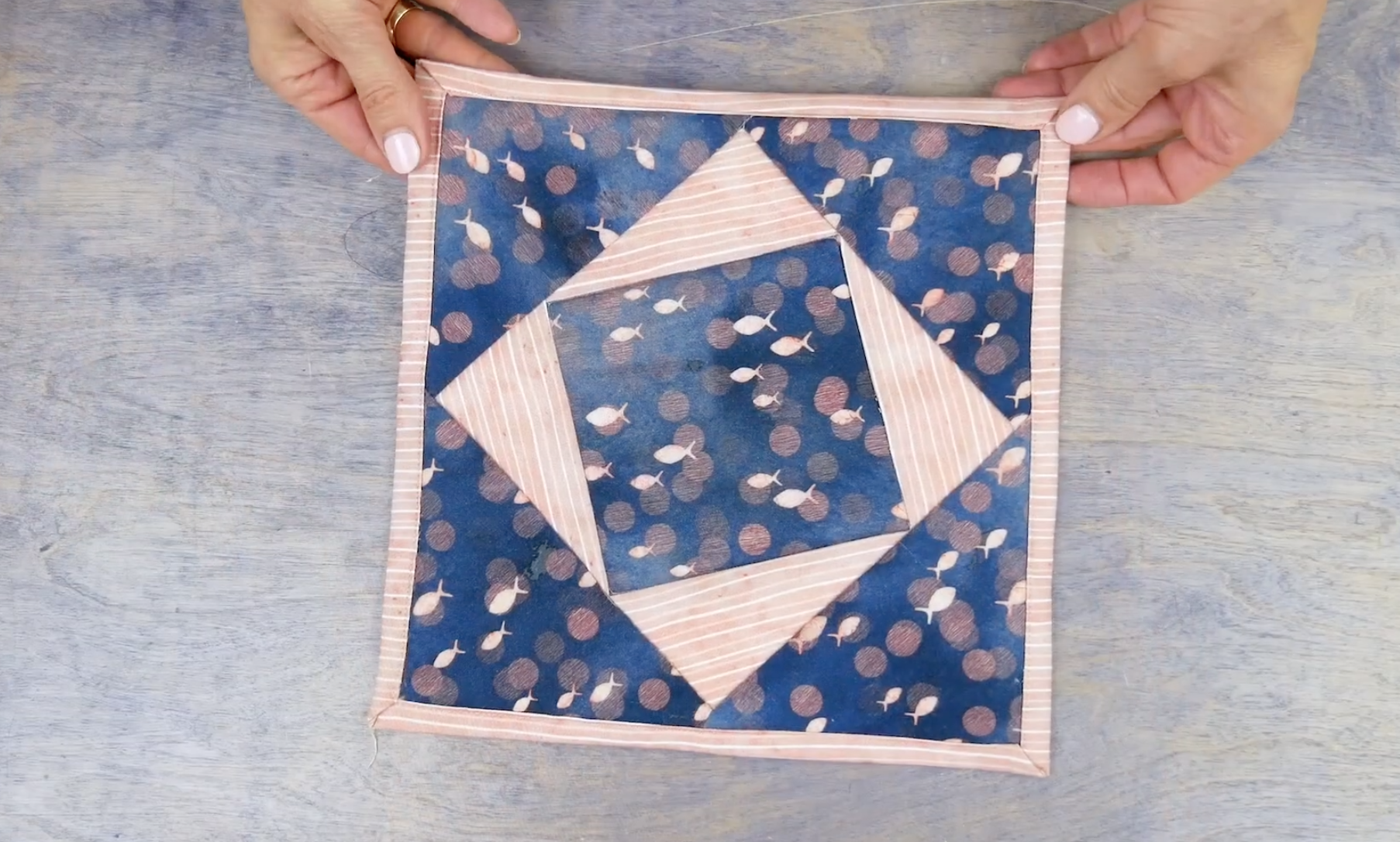

When you’ve finished, your quilt should have perfectly mitered corners and a binding that transitions evenly from back to front without an extra seam like you would with strip binding.

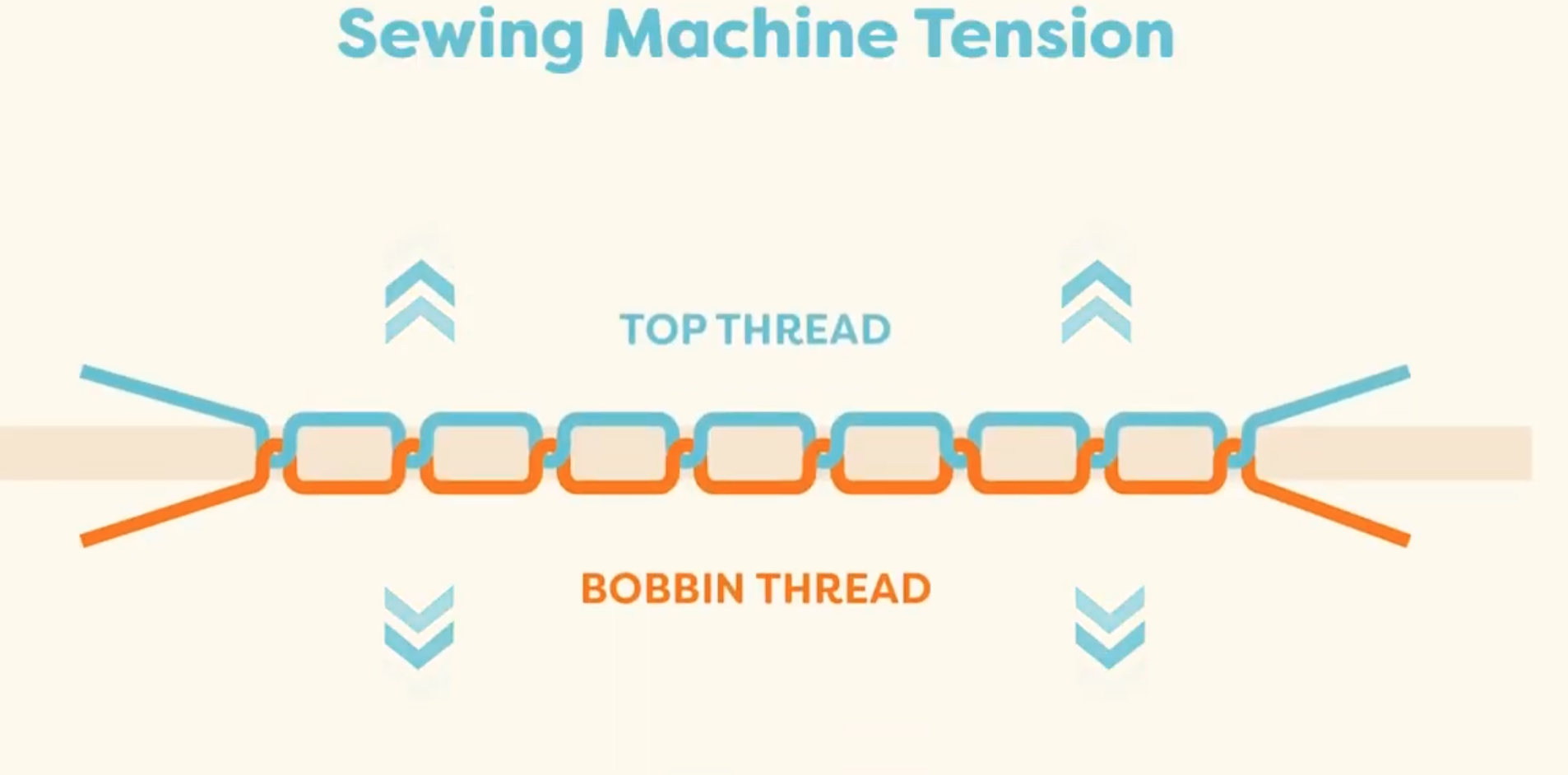

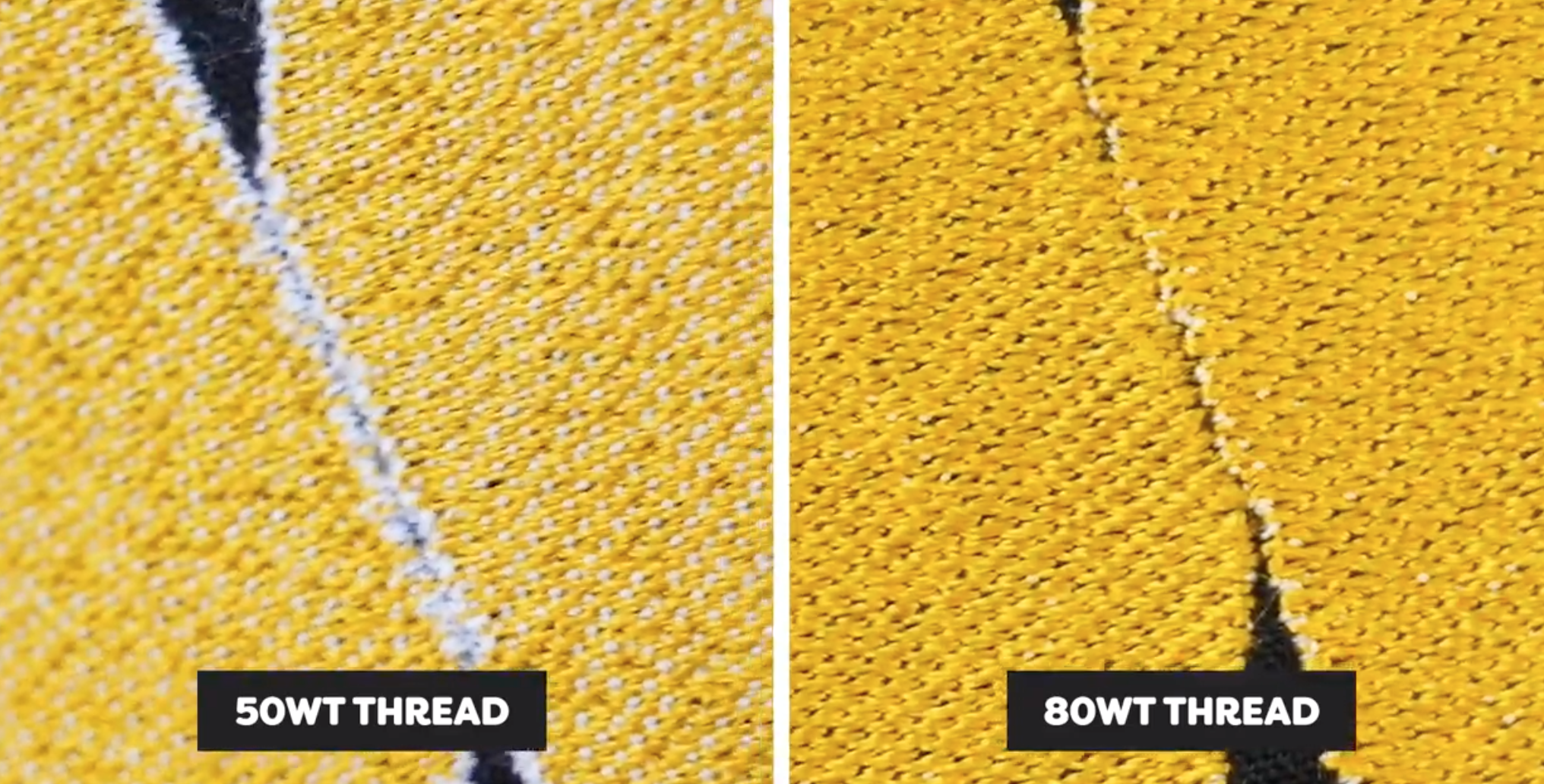

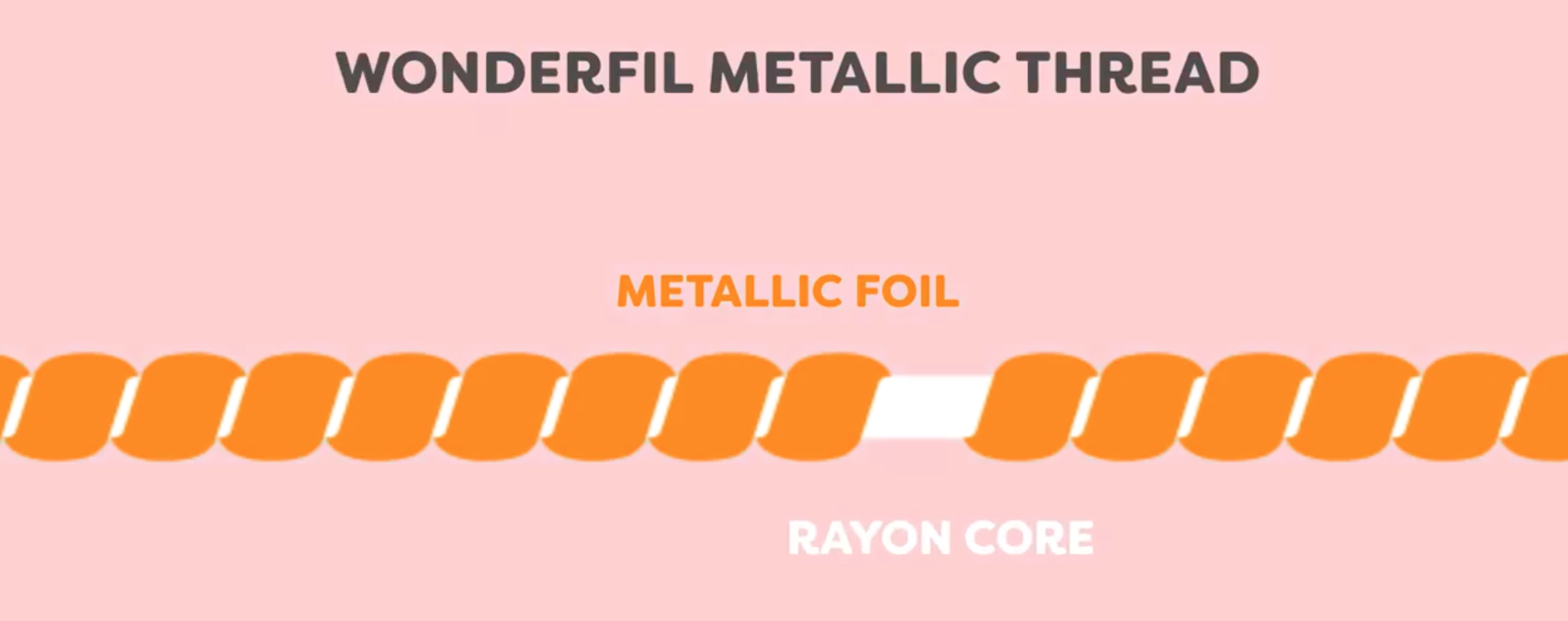

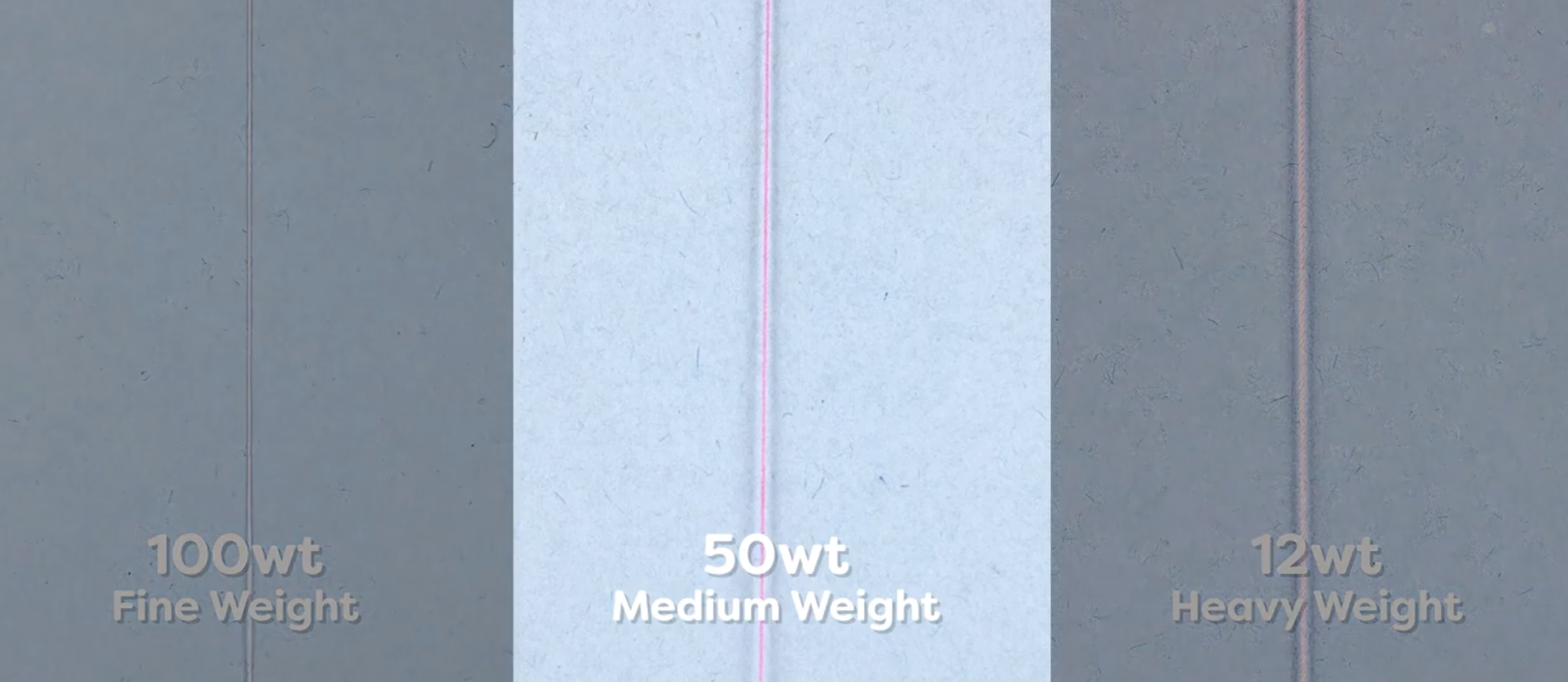

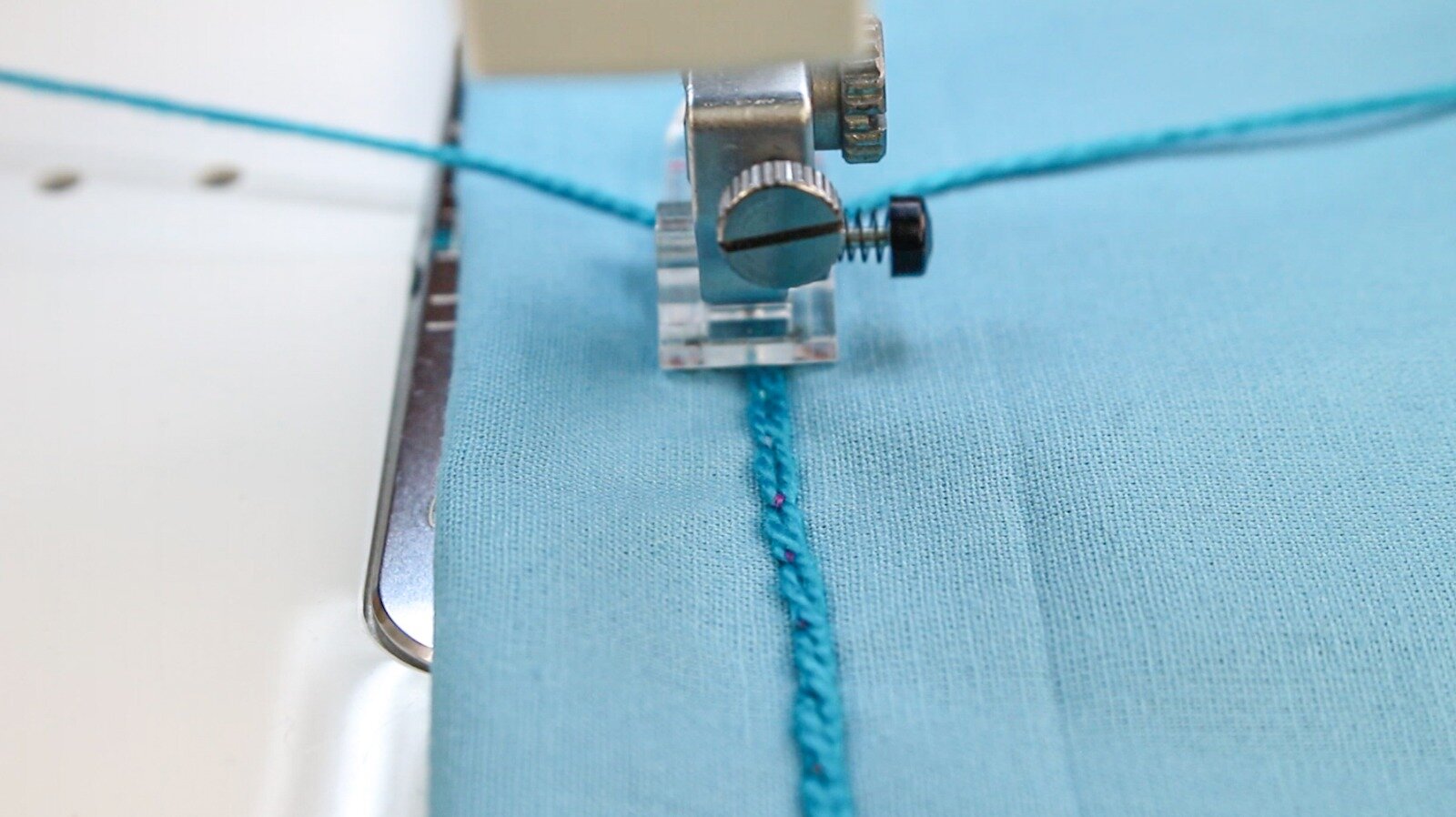

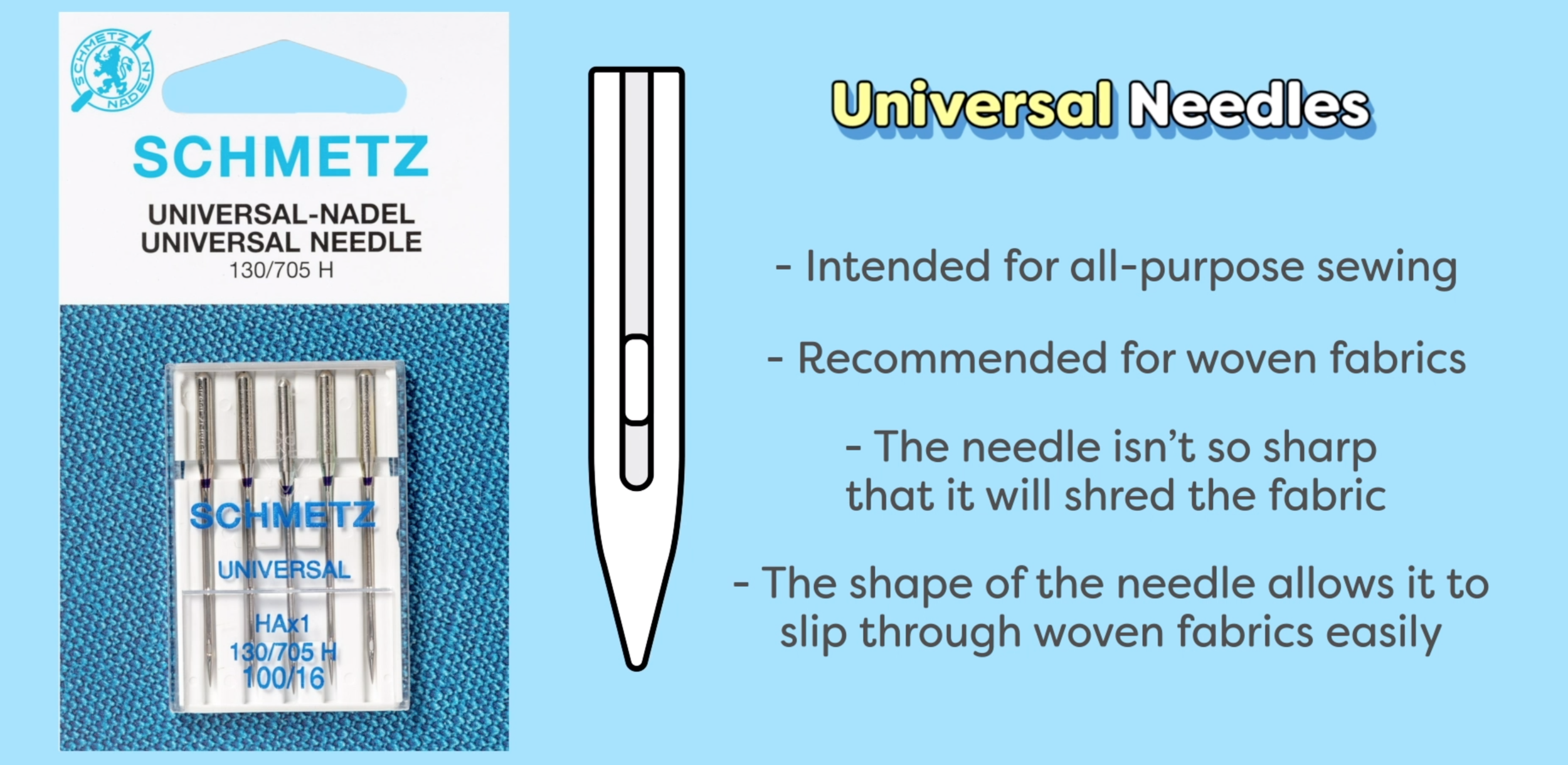

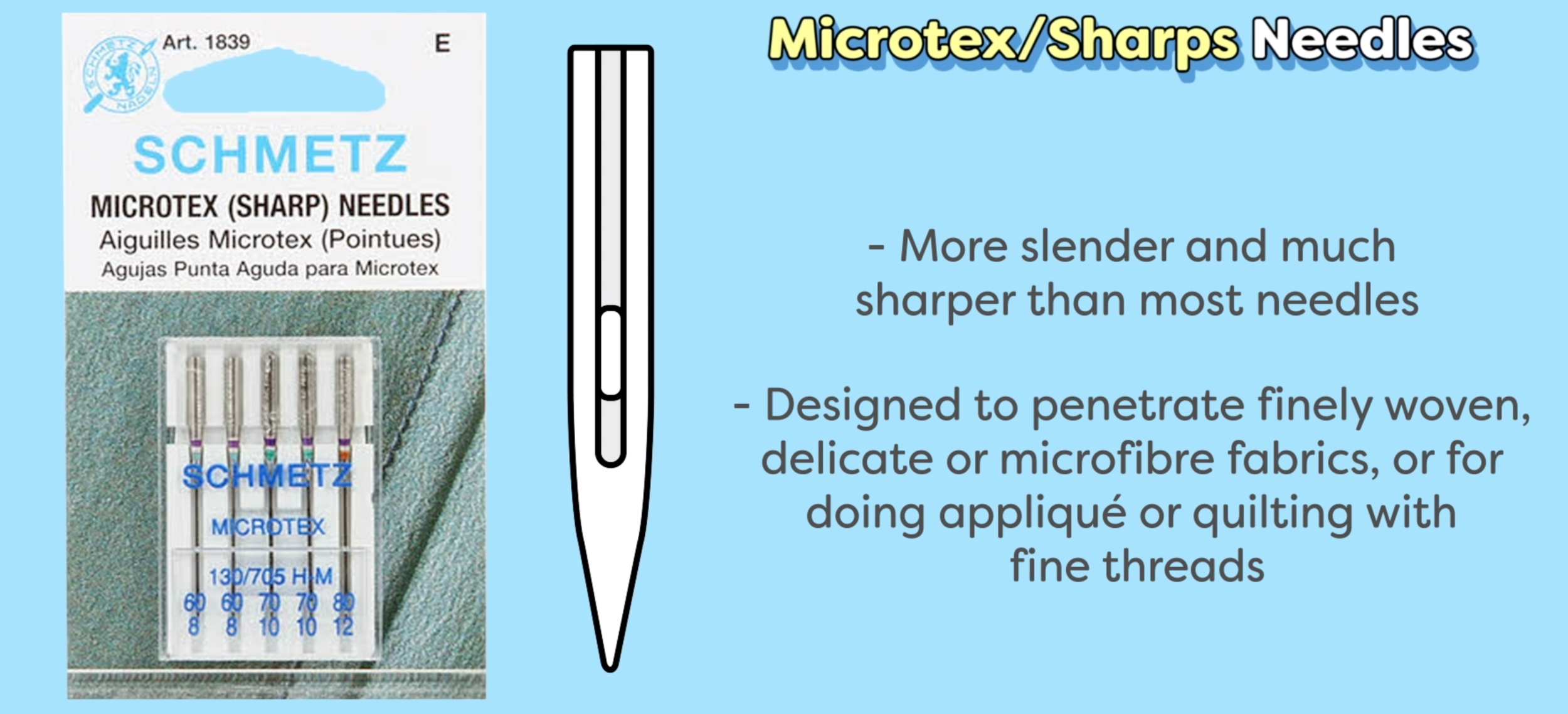

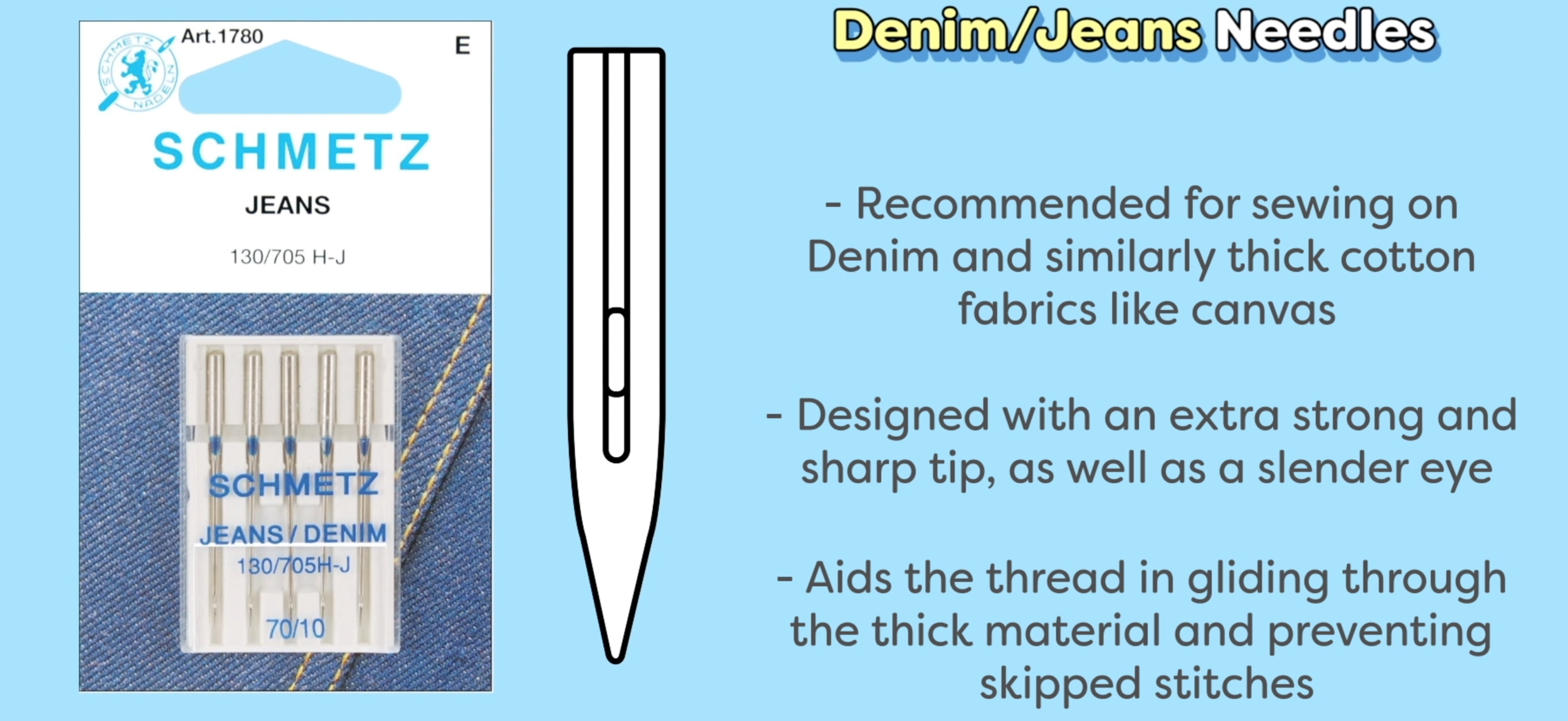

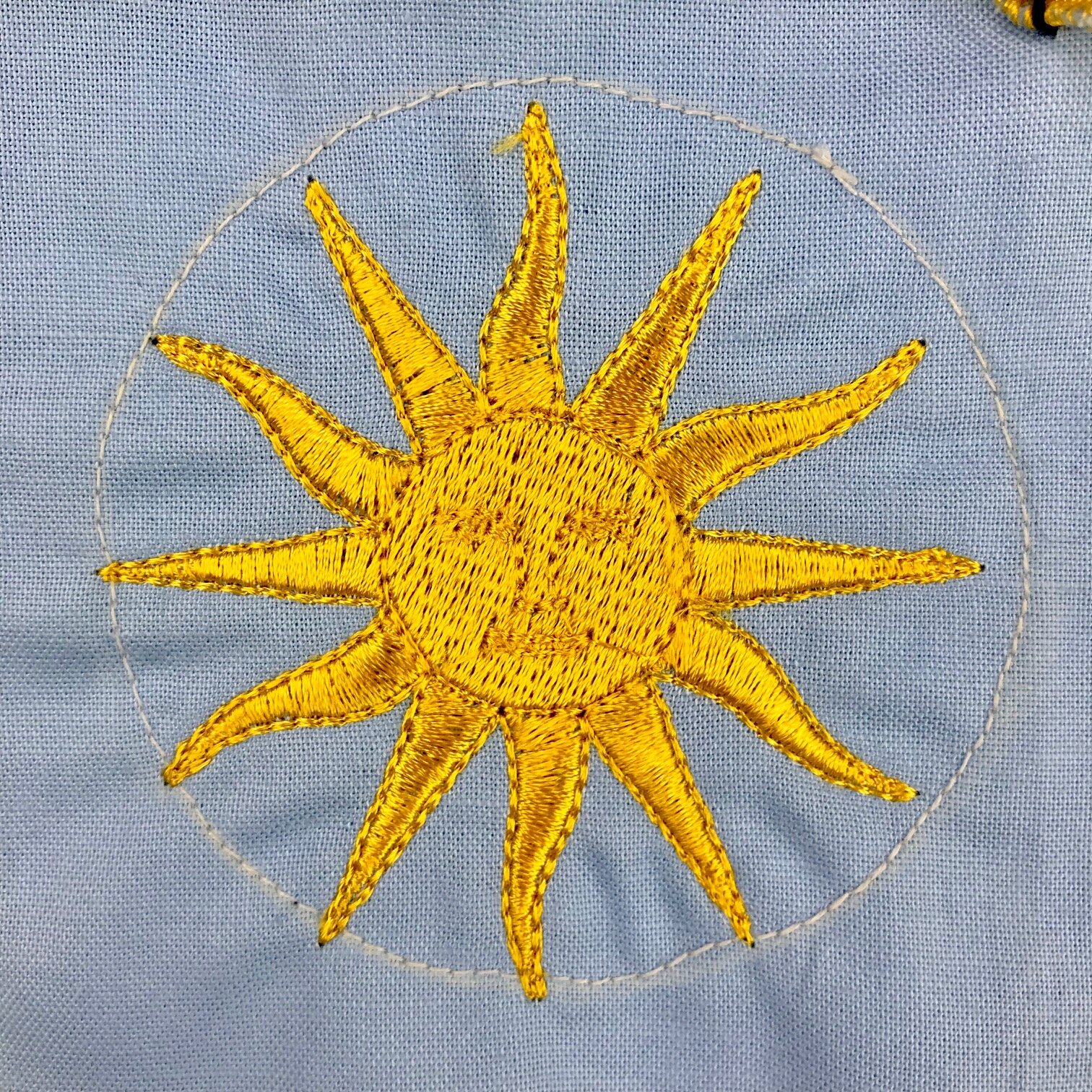

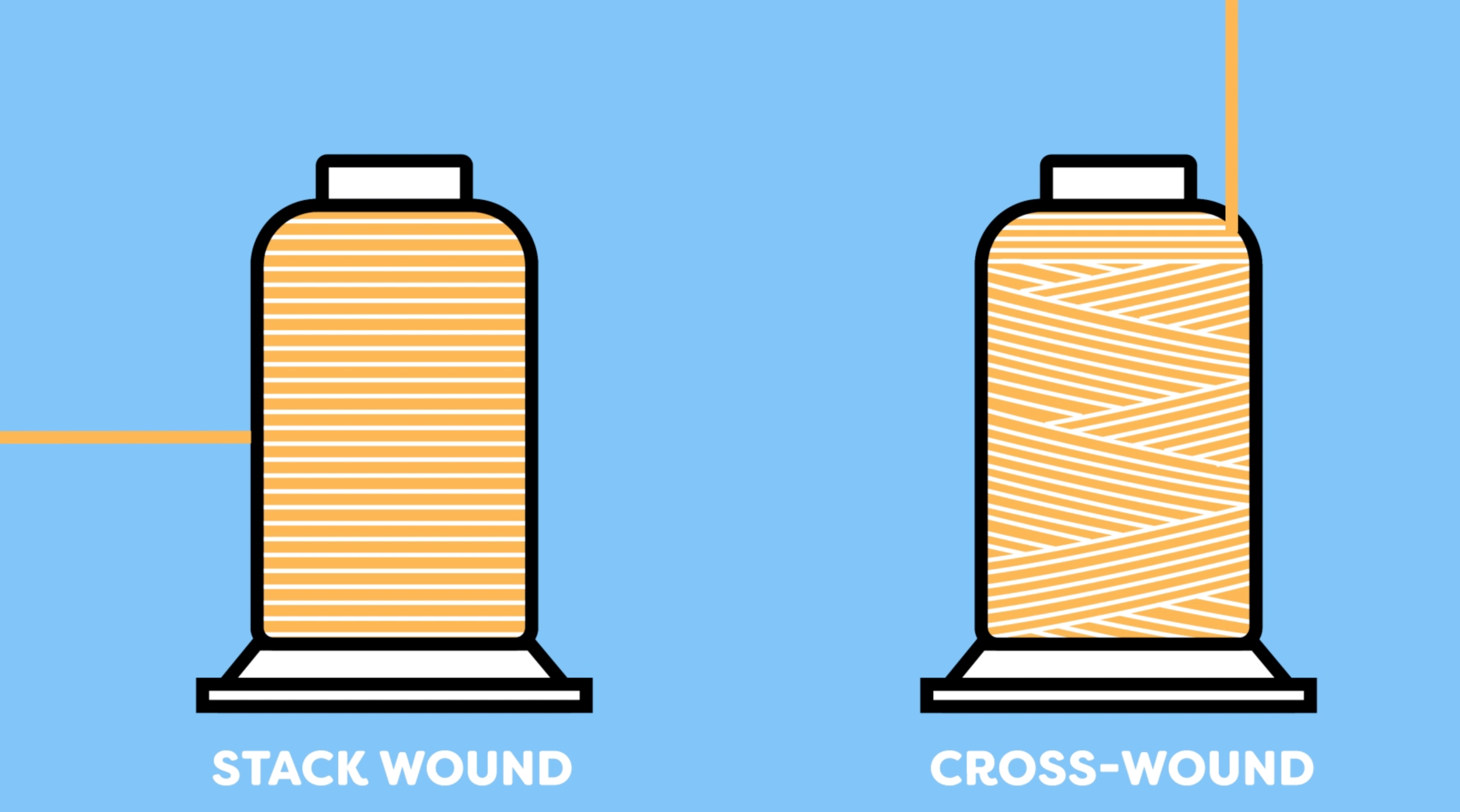

At this point you can choose to hand stitch your binding down like it’s traditionally done, or you can machine sew it which will go quicker. No matter which method you choose, we highly recommend using a finer thread in the top and bobbin. The thread we’ll be using is called DecoBob, which is an 80wt cottonized polyester thread. Because it’s so fine, it will really help to hide in the fabric so your stitches will be less visible. This is especially important if you choose to machine stitch your binding down. We recommend this thread because it’s strong enough to reliably hold your binding down without being too visible or worrying about the thread breaking.

To sew the binding down with your machine, you want to stitch as close as you can to the edge as you can. Because we tacked everything down with the glue earlier, the fabric is much less likely to shift as we sew. However, you can hold the edges down with some wonder clips if you need to. Sew all the way around your binding and don’t forget to back tack at the beginning and end.

There will be a gap at the mitered corners. These can be hand stitched close if you want to, or they can be left open if the quilt isn’t going to experience too much wear and tear. When you’re done, you have a beautifully bound quilt that smoothly transitions from back to front, and perfectly mitered corners. If you machine stitched it down with the 80wt DecoBob thread, you’ll also find that your stitches aren’t too visible either.

Inspired to sew with WonderFil threads? Find a store in your area that carries WonderFil at www.shopwonderfil.com/shop-local. You can also sign up for our free newsletter to receive more educational sewing tips, tutorials, and free patterns. Register by clicking here! We’ll see you again next time!